Electronic enclosures play a vital role in maintaining the performance and reliability of electronic devices. As technology advances and components become smaller yet more powerful, managing heat inside these enclosures becomes increasingly challenging. Effective heat dissipation ensures that internal circuits, processors, and other critical parts operate within safe temperature ranges, preventing premature failure or performance degradation.

Heat accumulation inside an enclosure can lead to system instability, reduced lifespan, and even safety risks. Therefore, proper enclosure design, material selection, and cooling strategies are crucial in thermal management. Engineers must consider not only the enclosure’s strength and protection level but also how efficiently it transfers or dissipates heat. By optimizing airflow, surface structure, and material conductivity, manufacturers can build enclosures that support stable performance even in high-temperature or high-load applications.

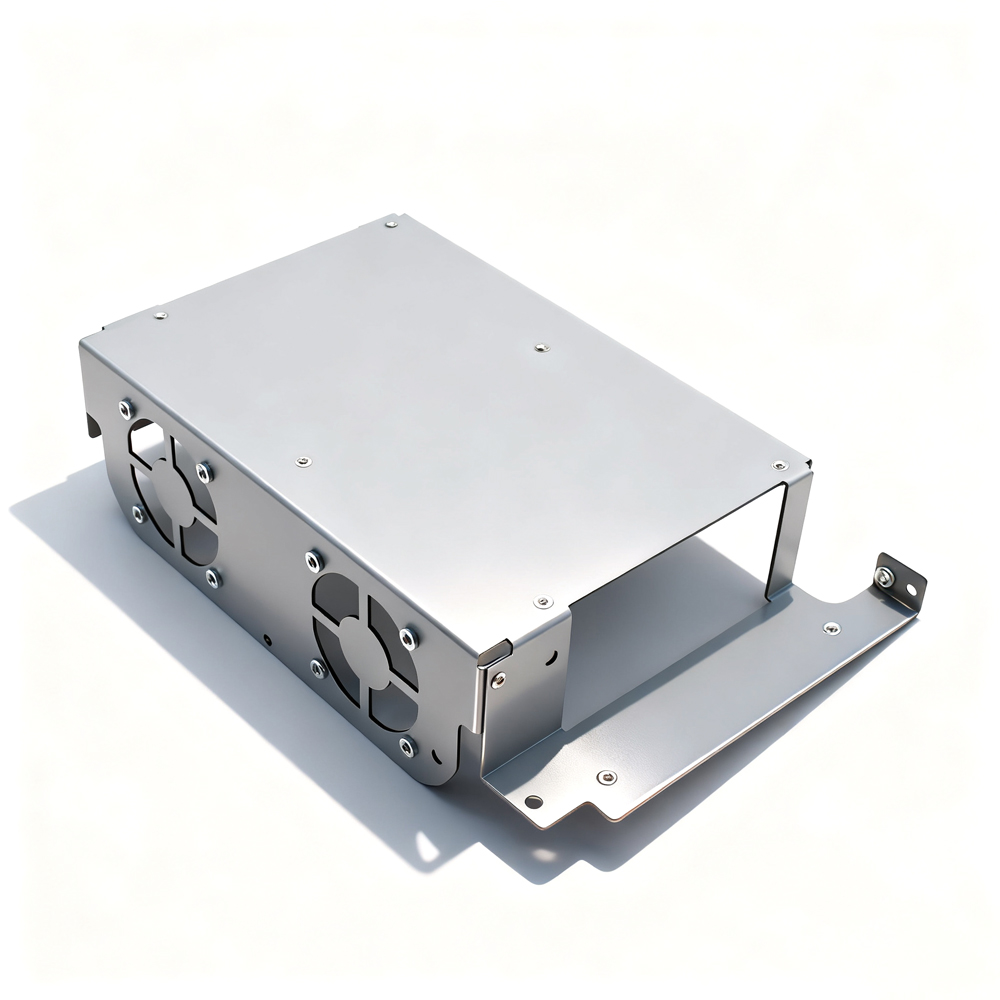

The material of an enclosure directly affects its ability to conduct and release heat. Metals such as aluminum and stainless steel have high thermal conductivity, making them ideal for electronic enclosures that generate significant heat. Stainless steel enclosures, in particular, offer an excellent balance between durability, corrosion resistance, and heat transfer efficiency.

A larger surface area allows better heat exchange between the enclosure and surrounding air. Enclosures with fins, perforations, or ribbed surfaces enhance natural convection, promoting faster heat release. Optimizing design geometry—such as including ventilation holes and proper spacing—helps maintain efficient airflow and cooling performance without compromising protection.

The placement of electronic components inside the enclosure also influences heat dissipation. Components that produce more heat should be positioned closer to ventilation paths or conductive surfaces. Using thermal interface materials (TIMs) between heat sources and enclosure walls helps accelerate heat transfer to the outer surface, maintaining temperature stability inside the system.

| Material Type | Thermal Conductivity (W/m·K) | Corrosion Resistance | Weight | Application Suitability |

|---|---|---|---|---|

| Aluminum | 205 | Moderate | Light | High-performance electronics, LED housings |

| Stainless Steel (304) | 16 | Excellent | Moderate | Harsh or corrosive environments |

| Copper | 385 | Poor | Heavy | Specialized heat-critical systems |

| Carbon Steel | 54 | Low | Heavy | General industrial enclosures |

| Magnesium Alloy | 156 | Moderate | Very Light | Aerospace and portable electronics |

This comparison highlights the trade-off between heat transfer efficiency and durability. While copper offers the highest conductivity, stainless steel provides a perfect combination of corrosion resistance, structural strength, and acceptable heat dissipation—making it ideal for industrial electronic enclosures exposed to moisture, chemicals, or outdoor conditions.

Natural convection relies on air movement caused by temperature differences. Designing enclosures with strategically placed vents, louvers, or mesh openings allows hot air to escape naturally while drawing in cooler air. This type of passive cooling is energy-efficient and maintenance-free, suitable for smaller or low-power electronic devices.

Every surface emits radiant heat proportional to its temperature. Enclosures can be treated with surface coatings that enhance emissivity, such as matte black or anodized finishes. Increasing radiation efficiency helps enclosures dissipate heat more effectively, especially in sealed systems where airflow is limited.

Integrating heat sinks directly into the enclosure design improves thermal transfer from internal components to the exterior. Stainless steel enclosures can incorporate extruded aluminum heat sinks, combining corrosion resistance with enhanced thermal performance. Proper contact between the heat source and heat sink surface is essential for optimal performance.

When passive cooling is insufficient, active systems such as fans or blowers can be installed. These systems increase airflow within the enclosure, rapidly removing heat from components. The direction and speed of air circulation must be carefully designed to avoid creating hot spots or uneven cooling zones.

For high-power electronics like servers or industrial drives, liquid cooling systems provide superior thermal management. Coolant flows through channels or tubes in direct contact with hot surfaces, transferring heat to an external radiator. Though more complex, liquid cooling is extremely effective in maintaining stable temperatures under heavy loads.

Thermoelectric (Peltier) cooling modules can be integrated into electronic enclosures for precise temperature control. These systems use electrical energy to create a heat flow between two surfaces, providing targeted cooling for sensitive components without requiring moving parts.

Optimizing airflow is fundamental to efficient enclosure cooling. Engineers can simulate internal air movement using computational fluid dynamics (CFD) software to ensure even temperature distribution. Strategic vent placement and internal channeling allow for better heat removal while preventing dust or moisture ingress.

While enclosures must release heat, they also need to protect against external temperature fluctuations. Insulating layers or reflective coatings can minimize heat absorption from sunlight or surrounding equipment. This dual control—retaining internal heat where needed and blocking external heat—is vital in outdoor or high-temperature industrial settings.

Compact enclosures reduce size and weight but may trap heat more easily. Spacious designs allow for better airflow and easier integration of cooling mechanisms. The optimal size depends on the power density and operating environment of the electronic system.

Manufacturers evaluate materials and designs through thermal conductivity tests. By measuring how quickly heat moves across an enclosure surface, engineers can refine designs for optimal performance.

Electronic enclosures undergo tests simulating real-world temperature extremes, humidity, and operational cycles. These evaluations ensure the enclosure maintains consistent performance across varying conditions, guaranteeing reliability and safety in demanding industrial environments.

Advanced stamping and welding processes help maintain the structural integrity of stainless steel enclosures. Precision manufacturing minimizes gaps and inconsistencies that could affect heat transfer or sealing performance.

Applying protective coatings enhances both corrosion resistance and thermal emissivity. Techniques like electro-polishing, powder coating, and anodizing can improve heat dissipation while providing a clean and durable surface finish.

In factories and automation lines, stainless steel enclosures house controllers, sensors, and relays that generate significant heat. Using heat-dissipating enclosures helps maintain system stability and prevents costly downtime due to overheating.

Routers, switches, and communication modules require enclosures that support continuous operation. Proper ventilation and thermal design allow such equipment to function reliably even in densely packed server environments.

Solar and wind power control units operate under high temperatures. Heat-dissipating enclosures ensure safe performance and extend the lifespan of electronic modules exposed to direct sunlight and outdoor environments.

Aluminum and stainless steel are the most common choices. Aluminum offers higher heat conductivity, while stainless steel provides better corrosion resistance and structural durability, making it ideal for industrial environments.

Ventilation holes and louvers enable air circulation, allowing heat to escape naturally. Properly designed airflow paths prevent hot spots and maintain a stable internal temperature without additional power consumption.

Thermal and environmental stress tests simulate real operating conditions to confirm that the enclosure maintains stable temperature control and mechanical strength under prolonged use.

Copyright © 2024 by Xiamen Tongchengjianhui Industry & Trade Co., Ltd. - Privacy policy