In today’s competitive electronics industry, custom electronics enclosures play a critical role not only in protecting internal components but also in establishing a brand’s visual identity and market recognition. A well-designed enclosure can transform a generic electronic product into a professional, high-end device that reflects the manufacturer’s quality, innovation, and style. The material, color, finish, and structural design of custom electronics enclosures all contribute to the perception of the product and, by extension, the brand itself.

By combining aesthetics with functionality, manufacturers can use stainless steel, aluminum, or other materials to enhance durability, promote heat dissipation, and ensure long-term performance. At the same time, a custom electronics enclosure becomes a marketing tool—its shape, surface texture, and labeling help consumers remember and trust the brand.

The choice of material for custom electronics enclosures directly influences how customers perceive product quality. Stainless steel and aluminum are often used due to their superior corrosion resistance, strength, and elegant appearance. For example, stainless steel enclosures convey a sense of reliability and professionalism, while anodized aluminum provides a modern and premium look that fits high-end electronics.

Using consistent materials across product lines reinforces brand identity. When customers recognize the same texture, color tone, and finish, they associate these elements with the company’s standards of excellence. This helps build customer loyalty and trust, making material selection a strategic branding decision as much as a technical one.

| Material Type | Common Finish | Durability Level | Branding Effect |

|---|---|---|---|

| Stainless Steel | Brushed / Polished | Very High | Professional, Reliable |

| Aluminum Alloy | Anodized / Powder Coated | High | Modern, Sleek |

| ABS Plastic | Matte / Gloss | Medium | Cost-Effective, Lightweight |

| Zinc Alloy | Chrome-Plated | High | Luxury, Decorative |

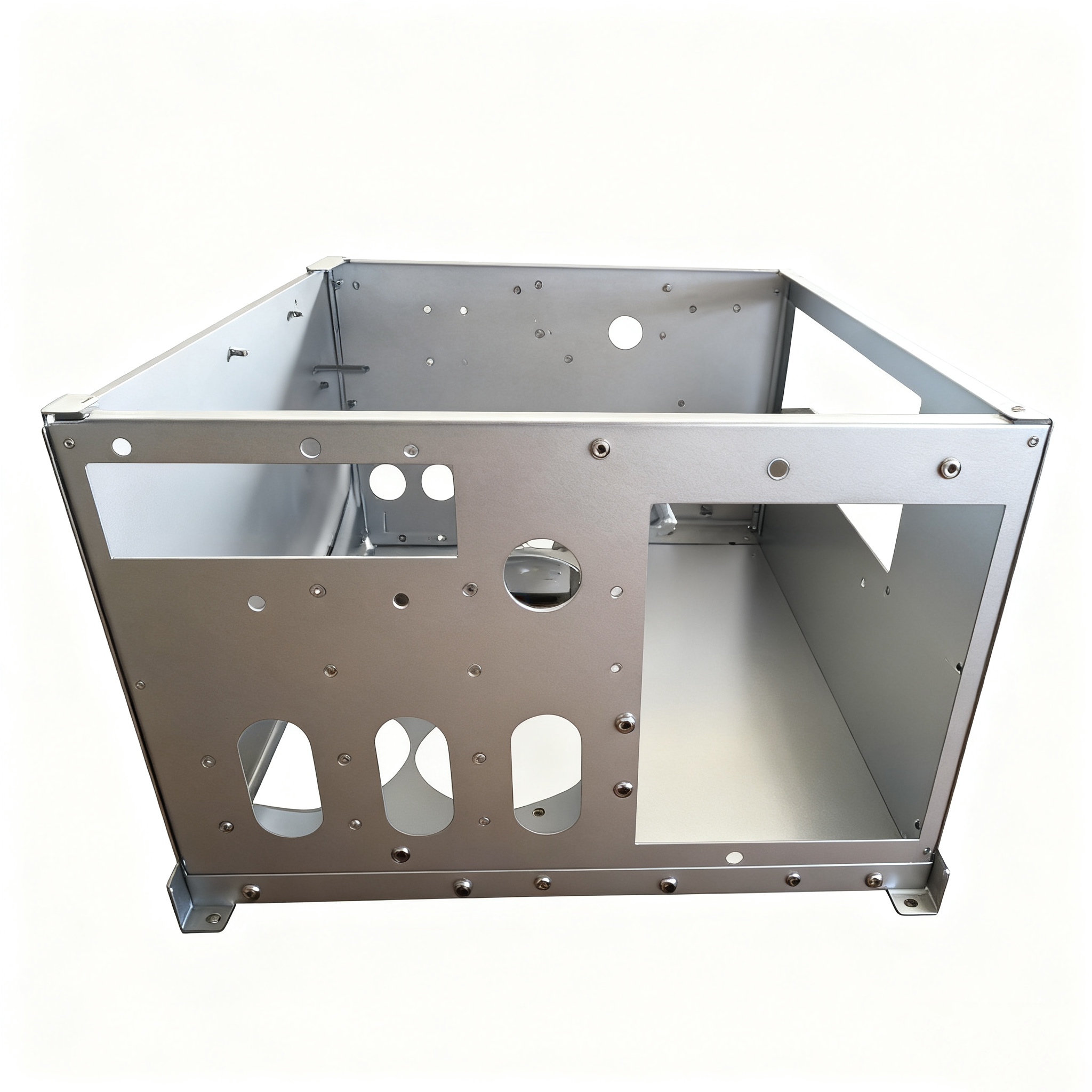

A custom electronics enclosure’s structure must balance aesthetics with practicality. Smooth edges, ergonomic curves, and well-placed fasteners make products visually appealing while maintaining user comfort and protection. Compact yet durable designs often stand out in crowded markets, symbolizing technical sophistication.

When enclosure design incorporates brand-specific geometry—such as signature corners or vent patterns—it further strengthens product differentiation. Over time, such design details become recognizable brand features, much like the unique shapes used in automotive or smartphone designs.

Surface finishing transforms a simple metal or plastic shell into a visual representation of brand quality. Common finishing methods include powder coating, sandblasting, polishing, and anodizing. Each technique offers distinct advantages in terms of texture, gloss, and corrosion protection.

For instance, a polished stainless steel finish reflects precision and luxury, while matte powder coatings convey stability and subtlety. Color choices are equally significant—companies often match their enclosures to corporate colors for instant brand association.

| Finishing Method | Texture Type | Visual Effect | Branding Benefit |

|---|---|---|---|

| Powder Coating | Matte | Durable, Non-Reflective | Professional Consistency |

| Anodizing | Gloss / Satin | Metallic Luster | Premium Look |

| Sandblasting | Rough | Industrial Feel | Rugged Brand Image |

| Polishing | Smooth | Mirror Finish | Luxury Appeal |

Custom logos, nameplates, and engraved marks turn electronics enclosures into silent brand ambassadors. Laser engraving and silk-screen printing are popular techniques for embedding branding elements that resist wear and fading. These visual identifiers help users recognize a product’s manufacturer immediately, even in competitive markets.

Strategic logo placement—such as on the enclosure’s front panel or near interface ports—ensures visibility without disrupting the product’s clean aesthetic. When executed effectively, these details contribute to a unified and lasting brand image.

Precision manufacturing not only ensures mechanical reliability but also reflects brand professionalism. Tight tolerances, smooth edges, and uniform assembly demonstrate technical competence, which builds customer confidence in both the product and the company.

For instance, high-precision CNC machining or laser cutting guarantees that each enclosure piece fits perfectly, minimizing defects. Such consistency across production batches reinforces the impression of a reliable and detail-oriented brand, particularly in the B2B electronics market.

A brand’s reputation depends heavily on how consistently it delivers quality. Even small imperfections—uneven coatings or misaligned panels—can negatively impact brand perception. Therefore, strict inspection processes, including dimensional verification, coating thickness measurement, and durability testing, are essential.

By adopting advanced manufacturing technologies, such as robotic polishing and automated assembly, companies can maintain a uniform appearance and texture that enhances perceived value.

Heat management is another important factor in enclosure performance and branding. A product that operates efficiently without overheating demonstrates engineering excellence, reflecting well on the brand. Custom enclosures can include heat sinks, vents, or conductive materials that promote effective heat dissipation while maintaining visual appeal.

A well-designed electronics enclosure must combine function with beauty. For example, vent patterns can be designed in a way that aligns with brand symbols or aesthetic elements. This approach allows technical components to double as branding tools—functionality and identity work together to make the product memorable.

For portable devices, custom enclosures help distinguish brands in crowded retail environments. Consumers often judge products based on their outer appearance before evaluating technical specifications. High-quality materials, smooth finishes, and recognizable logos enhance consumer trust and influence purchasing decisions.

In industrial sectors, branding is just as vital. Durable enclosures that resist corrosion and mechanical stress reflect reliability and professionalism. This visual strength communicates to clients that the brand values performance and durability, both essential traits for long-term partnerships.

Custom electronics enclosures enhance brand visibility, protect internal components, and ensure design consistency across product lines. They also improve heat dissipation and facilitate user-friendly operation, creating a professional image that increases product credibility in the marketplace.

Different materials offer unique branding effects. Stainless steel creates a reliable and premium feel, while aluminum emphasizes modernity and precision. Selecting the right material helps align the physical appearance of the product with the company’s overall brand identity.

Manufacturers can choose from a wide range of customization features, including finishes, colors, logo engraving, and labeling. These details help establish a distinctive visual identity and differentiate products from competitors.

Copyright © 2024 by Xiamen Tongchengjianhui Industry & Trade Co., Ltd. - Privacy policy