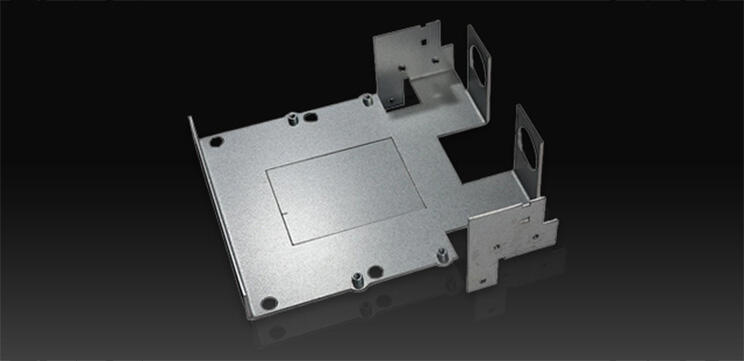

Custom High Quality Metal Enclosures Stainless Steel Aluminum for Industrial Use

With over 100 advanced machines, like laser cutters, bending machines, and welders, in our China-based network, we can supply any quantity of sheet metal parts, from low-volume prototypes to high-volume production. Our domestic fabricators and engineers provide precision and fast delivery.

|

|

|

Stamping |

Bending |

Laser Cutting |

| Stamping uses dies and presses to shape flat metal sheets into different forms, creating complex, three-dimensional designs through cold-forming techniques. |

Bending applies a force to a thin sheet of metal to shape it into various geometries, like U-shape, V-shape, or channel shape. The thickness of the metal can vary. |

Laser cutting uses a focused laser beam to cut, etch, or engrave materials, vaporizing or melting them for precise edges and complex patterns based on designer specifications. |

Sheet Metal Fabrication materials

We can generate instant Sheet Metal Fabrication quotes for 10+ metals

| Material |

Grade |

Feature |

Application |

| Stainless Steel |

SUS 201, 304, 316 |

Excellent corrosion resistance Durable |

Kitchen appliances Medical parts Outdoor fasteners |

| Aluminum |

5052, 1060, 6061 |

Lightweight Corrosion-resistant |

Electronics Automotive parts LED housings |

| Brass |

H62, H65 |

High electrical conductivity Corrosion resistance |

Electrical contacts Decorative hardware |

| Copper |

T2, C1100 |

Excellent conductivity Thermal performance |

Heat sinks Electronic components |

| Cold Rolled Steel |

SPCC, Q195, Q235, DC01 |

Smooth surface Good dimensional Accuracy Easy forming |

Brackets Enclosures Covers |

| Hot Rolled Steel |

Q235, Q345 |

Higher strength Rougher surface Lower cost |

Structural parts Chassis Agricultural tools |

| Galvanized Steel |

SGCC, DX51D+Z |

Corrosion resistant Shiny surface |

HVAC parts Electrical boxes Panels |

Surface Finishes

We can instantly quote a wide variety of post-machining surface finishes.

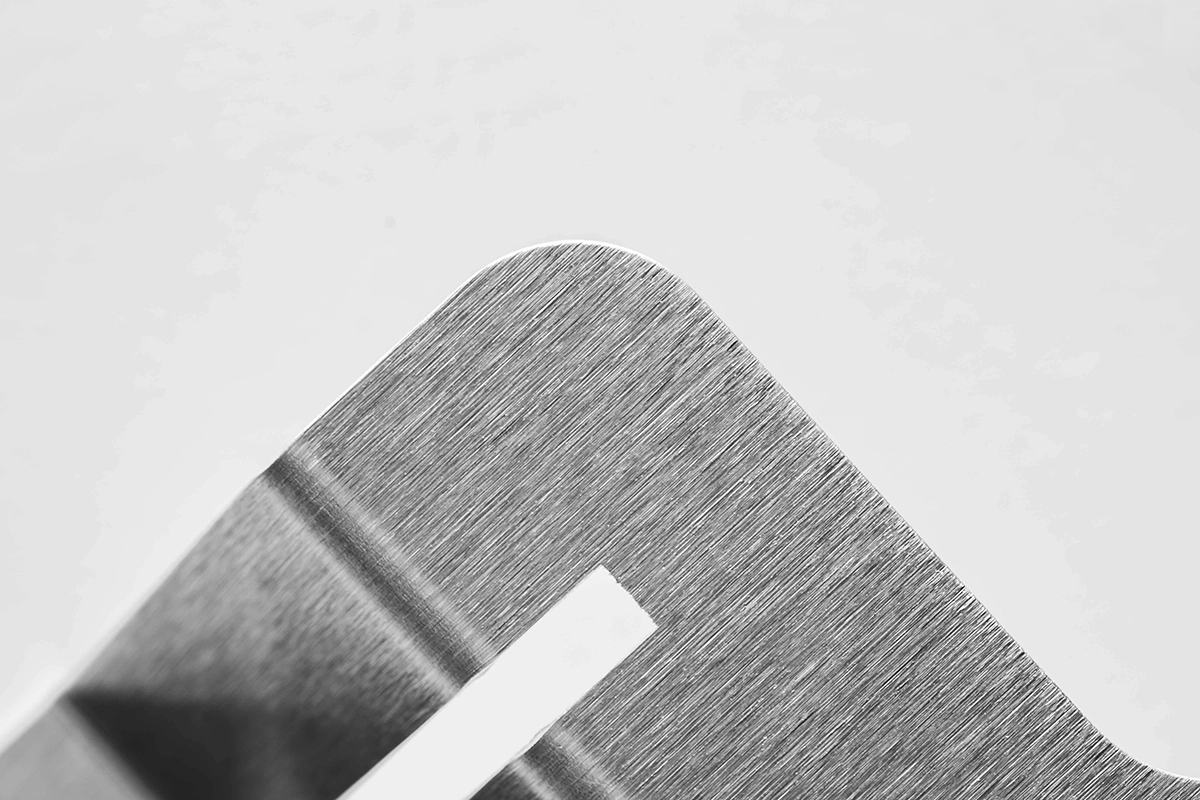

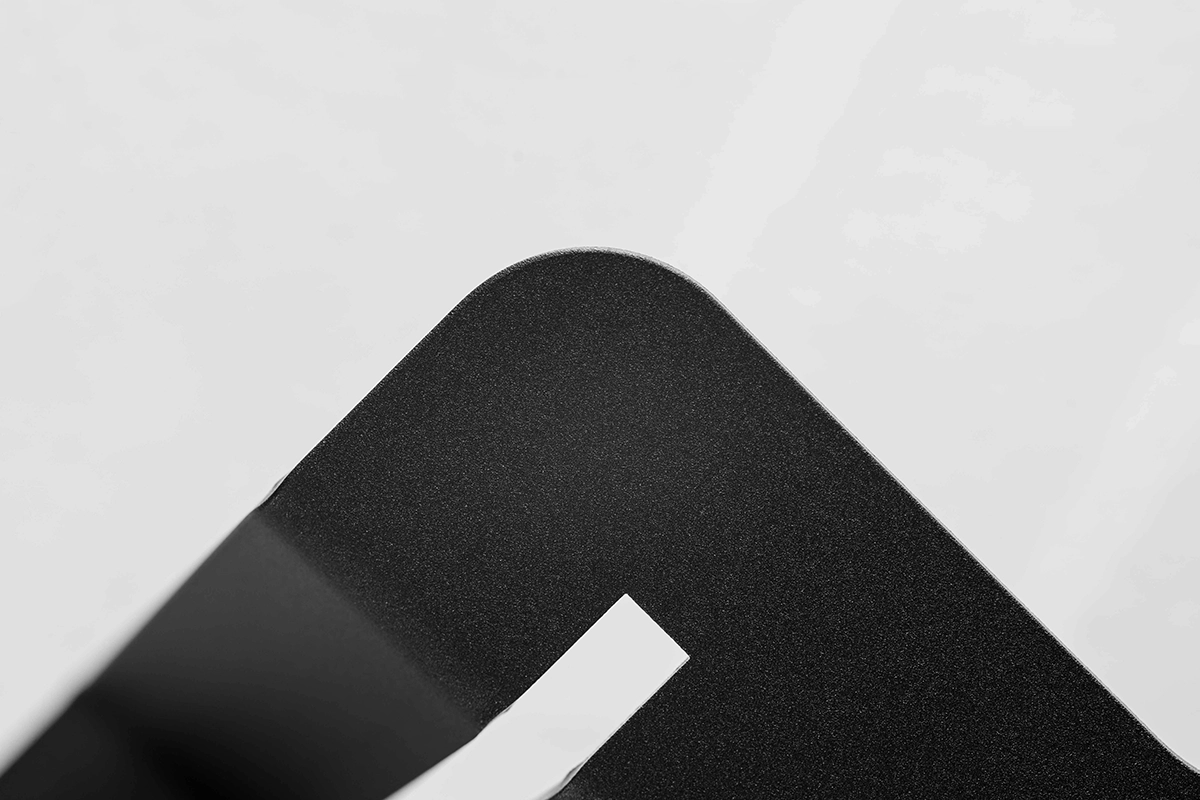

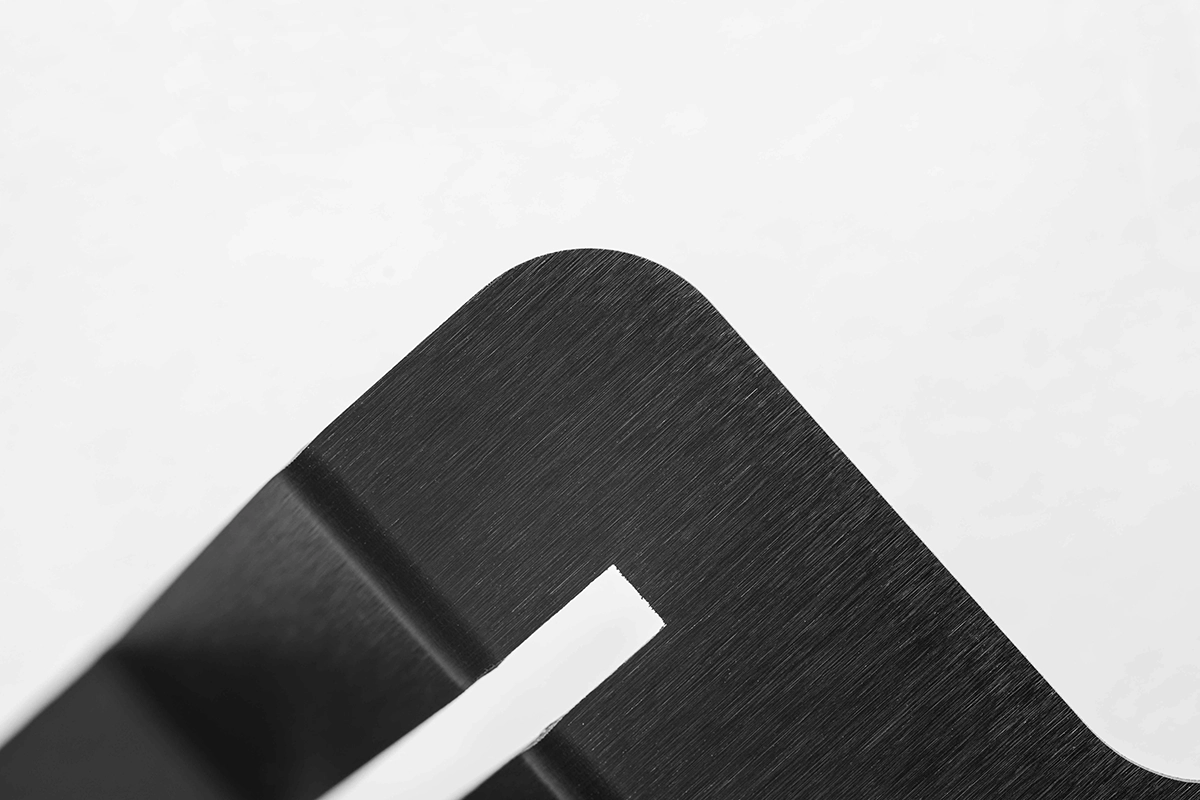

| Standard |

Bead blasted |

Brushed |

|

|

|

| This is our standard finish. Parts as delivered as cut and bent, no additional treatment applied. Sharp edges are broken and deburred for safe handling |

Parts are bead blasted with glass beads which results in a grainy texture. Sharp edges are broken and deburred for safe handling. |

Parts are manually brushed with grit #180 after cutting and bending. Sharp edges are broken and deburred for safe handling. Ideal to reduce the surface roughness of a part. |

| Anodized type III (Hardcoat) |

Bead blasted + Anodized type II |

Brused + Anodized type II |

|

|

|

| Parts dipped in an anodizing (type III) bath directly after fabrication. Ideal to improve corrosion and wear resistance of components. Sharp edges are broken and deburred for safe handling. |

Parts are dipped in an anodizing bath (type II) after bead blasting. Ideal for increasing the corrosion resistance of the part. Sharp edges are broken and deburred for safe handling. |

Parts are dipped in an anodizing bath (type II) after manual brushing. Ideal for increasing the corrosion resistance of the part. Ideal for increasing the corrosion resistance of the part. Sharp edges are broken and deburred for safe handling |

| Powder coated |

Black oxide |

Chromate conversion coating |

|

|

|

| Powder coating layer is applied directly after fabrication. Sharp edges are broken and deburred for safe handling. |

Parts are dipped in a black oxide bath after fabrication. Ideal to improve improve corrosion resistance and minimize light reflection in steel components. Sharp edges are broken and deburred for safe handling. |

Parts are dipped in an alodine bath directly after fabrication. Ideal to increase the corrosion resistance of the part while maintaining its conductive properties. RoHS compliant. Sharp edges are broken and deburred for safe handling. |

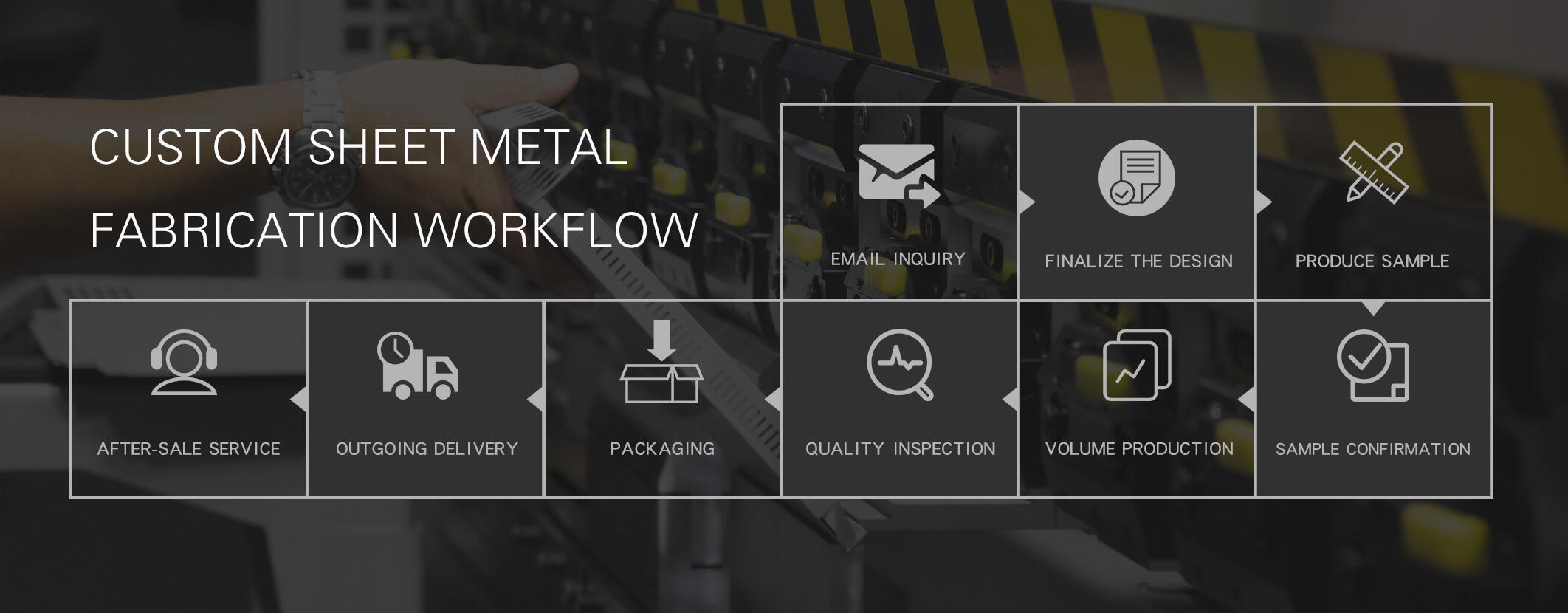

1 day for 2D to turn into 3D

| Professional Engineer Team Eliminate tolerance risks with ±0.01mm accuracy for GD&T compliance.Achieve unattainable structures with thin-walled components and complex geometries |

|

Sheet Metal Solutions

|

|

|

Rapid Prototyping |

Low Volume Fabrication |

High-volume Production |

| Get high-quality sheet metal prototypes in as little as 3 business days. With no minimums, this quick, affordable service streamlines design validation and reduces costs for efficient product iteration. |

Ideal for bridging to full production or scheduling small batches, our low-volume sheet metal service flexes to fit your timeline, ensuring consistent, on-time delivery with top-notch quality. |

Our advanced, all-in-one service provides fast, precise high-volume sheet metal fabrication, including finishing and assembly, meeting your specs while saving time and costs on large-scale orders. |

|

|

|

|

Quantity: 1-50 pcs

Lead Time: 3-7 days

|

Quantity: 50-5000 pcs

Lead Time: 1-3 weeks

|

Quantity: 5,000+ pcs

Lead Time: 4-8 weeks

|

Sheet Metal Fabrication Capabilities

|

|

General Tolerance |

High-Precision Tolerance |

| General Tolerances |

Metals : ISO 2768-c |

|

| Laser Cutting |

±0.1 mm |

±0.05 mm |

| Wire-Cut EDM |

±0.005 mm |

±0.002 mm |

| Stamping Precision |

±0.05 mm |

±0.02 mm |

| Riveting |

±0.05 mm |

±0.02 mm |

| Bend Angle |

±0.5° |

±0.25° |

| Bend to Edge |

±0.2 mm |

±0.1 mm |

| Bend to Hole |

±0.2 mm |

±0.1 mm |

| Welding (TIG) |

±0.5 mm |

±0.2 mm |

| Welding (Laser) |

±0.2 mm |

±0.1 mm |

| Welding (MIG) |

±1.0 mm |

±0.5 mm |

Trusted Sheet Metal Parts, Made Right

We focus on quality at every step to deliver precise sheet metal parts, from design to production.

We follow Design for Manufacturability (DFM) principles, dedicating time to understand your requirements and provide the best solutions for your project.

Our capabilities include computer-controlled manufacturing processes such as laser cutting, bending, punching, welding, stamping, and riveting. Advanced inspection tools—like CMM, two-dimensional measuring instruments, XRF analyzers, gauges, micrometers, and calipers—ensure all parts meet strict requirements.

With years of experience and ISO-certified fabrication facilities, we complete every project to the highest quality standards. custom sheet metal parts built to your specifications.

|

|

|

|

Tolerances of 1 inch or less

10+ inspection equipment

20+ quality engineers

ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

|

|

Factory strength

Our extensive network of sheet metal shops throughout China allows us to manage any project—from prototypes to full-scale production—with precision and flexibility. We transform your CAD designs into finished parts using advanced techniques including CNC machining, stamping, cutting, bending, welding, and riveting.

We also provide a variety of finishing options to enhance both function and appearance. Whether you need a single prototype or high-volume runs, we ensure on-time delivery of quality results every time.

120+

Countries Shipped

|

|

3000m2

Factory area

|

100+

Enterprise Employees

|

50+

Machines Set

|

80W+

Annual Output

|

|

|

|

|

| Stamping machine |

cnc machine |

Laser Cutting |

Tool and Die Shop |

|

|

|

|

| QC |

Electroplating |

Raw Materials Warehouse |

Packing Transport |