Specialized devices often require more than just a protective casing—they demand a tailored solution that balances strength, functionality, and aesthetics. A Custom Metal Enclosure provides exactly this combination. It not only shields internal components from physical and environmental damage but also enhances usability by integrating features specific to each device’s requirements.

In industries where precision and reliability are crucial, standard enclosures frequently fall short. Devices in telecommunications, healthcare, energy, and automation often need enclosures that match unique configurations, wiring systems, or thermal conditions. A Custom Metal Enclosure allows manufacturers to design with purpose, ensuring every detail contributes to the efficiency, safety, and longevity of the device.

Specialized devices are often deployed in challenging conditions. A Custom Metal Enclosure delivers the durability required to resist impacts, vibration, and environmental exposure. For sensitive equipment like diagnostic medical devices or communication servers, the enclosure becomes a critical line of defense.

Unlike generic housings, these enclosures can be designed with reinforced joints, sealed edges, or corrosion-resistant finishes. Such enhancements extend the device’s life cycle and reduce maintenance costs, creating long-term value for businesses.

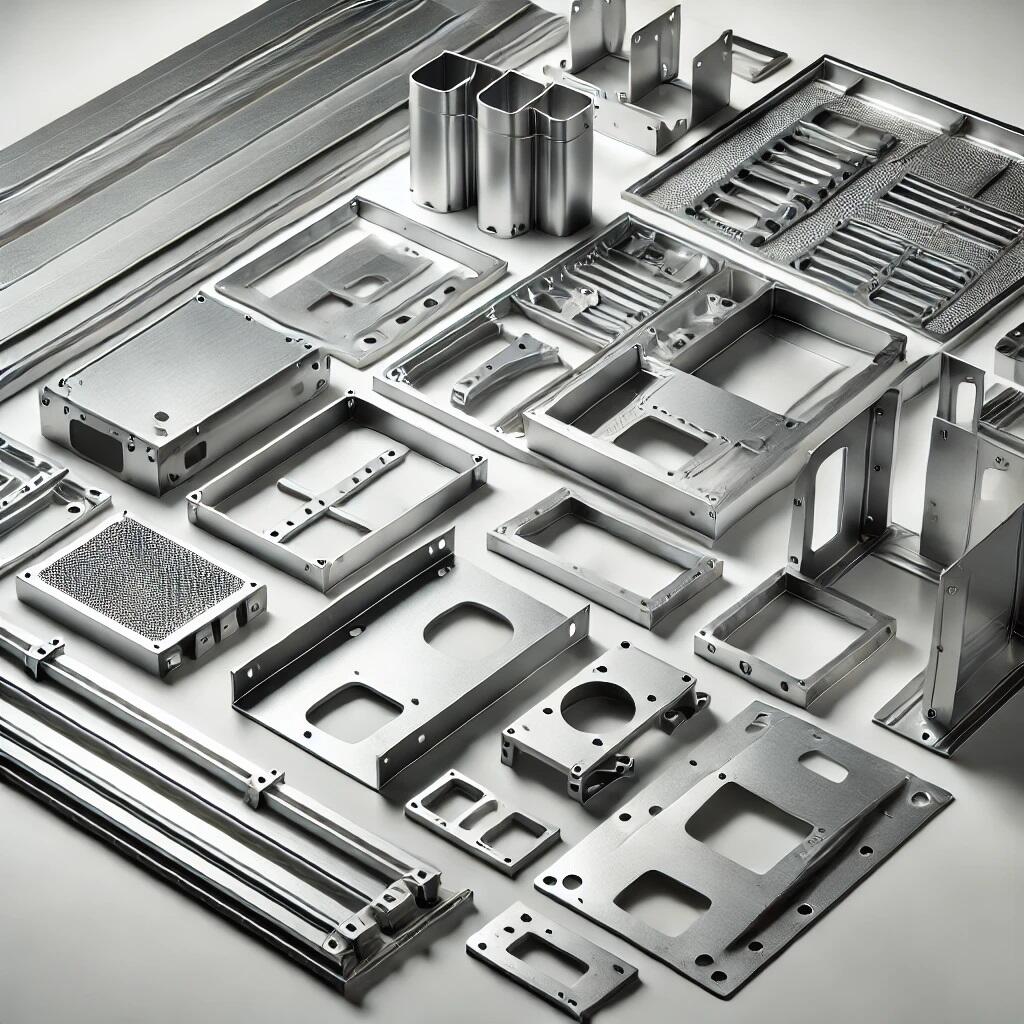

No two devices are exactly alike, and this is where customization plays a pivotal role. A Custom Metal Enclosure can be tailored with precise dimensions, unique cutouts, and specialized fittings. This ensures the enclosure not only fits the device but also optimizes its performance.

For example, ventilation slots can be incorporated for thermal management, or access panels can be positioned to simplify servicing. This adaptability makes the enclosure an integral part of the device’s overall design rather than just a protective shell.

When designing a Custom Metal Enclosure, functionality is prioritized alongside protection. Features like cable glands, locking mechanisms, display windows, or built-in hinges can be seamlessly integrated. Each addition supports the specific operational requirements of the device.

By focusing on integrated functionality, manufacturers reduce the need for aftermarket modifications, saving time and resources. This ensures that the final enclosure is both efficient and user-friendly.

Devices often face environmental challenges such as moisture, dust, or extreme temperatures. A Custom Metal Enclosure can be engineered to meet international protection standards like IP ratings, offering reliable performance in harsh conditions.

This environmental adaptability is especially critical in outdoor telecommunications, renewable energy systems, and industrial automation. The enclosure becomes a guarantee that sensitive technology will continue to perform under stress.

Medical devices must operate flawlessly in sterile environments. A Custom Metal Enclosure provides the hygiene and durability required, with smooth finishes and sealed designs that support easy cleaning. Additionally, it protects delicate diagnostic or monitoring equipment from contamination and physical damage.

In laboratories, enclosures also support modular designs, allowing researchers to safely house experimental setups while maintaining accessibility for adjustments.

In telecommunications, system uptime is non-negotiable. A Custom Metal Enclosure ensures routers, servers, and network equipment are shielded from interference and mechanical disruption. With tailored designs, enclosures can include fan mounts, modular racks, and cable management systems, streamlining installation and maintenance.

For networking infrastructure, this level of customization not only improves efficiency but also ensures compliance with safety and performance standards.

Parameter |

Typical Option / Range |

Application Benefit |

Protection Level (IP Rating) |

IP54 – IP67 |

Ensures resistance to dust, water, and harsh use |

Thermal Management Features |

Ventilation Slots, Heat Sinks, Fan Mounts |

Prevents overheating of sensitive electronics |

Locking & Security Options |

Standard Locks, Tamper-Proof Fasteners |

Enhances safety for specialized devices |

Mounting Configurations |

Rack-Mount, Wall-Mount, Portable Designs |

Provides flexible installation in diverse setups |

Customization Add-ons |

Cable Glands, Hinges, Viewing Windows |

Tailors enclosures to unique functional needs |

Though customization implies added complexity, modern fabrication techniques allow a Custom Metal Enclosure to be produced efficiently. CNC machining, laser cutting, and modular assembly streamline production while ensuring accuracy. This reduces lead times and enables businesses to scale solutions quickly.

Efficiency in production also means businesses can adapt rapidly to new device designs, ensuring they stay ahead in competitive markets.

While initial costs may be higher than off-the-shelf options, the return on investment is significant. A Custom Metal Enclosure reduces downtime, minimizes repair needs, and extends device longevity. For mission-critical equipment, these savings far outweigh the upfront expense.

In addition, the ability to align the enclosure with branding or operational requirements further increases the product’s market value.

Materials commonly used in Custom Metal Enclosure fabrication, such as aluminum and stainless steel, are recyclable and environmentally friendly. Choosing these materials supports sustainability goals while maintaining high performance standards.

Many businesses now view sustainability not just as compliance but as a value proposition, making recyclable enclosures an attractive choice.

Advanced manufacturing facilities adopt energy-efficient processes that minimize waste and reduce emissions. By using precision cutting and optimized material use, fabricators ensure the environmental impact of producing a Custom Metal Enclosure is as low as possible.

This commitment to sustainable production resonates strongly with customers who prioritize eco-conscious solutions.

Devices in telecommunications, medical technology, laboratory research, and industrial automation gain the most. These devices often require specific design adaptations to ensure reliable and efficient operation.

By integrating security features such as tamper-proof fasteners, locking systems, and sealed designs, custom enclosures protect devices not only from environmental factors but also from unauthorized access.

Yes, modern fabrication allows cost-effective production even for prototypes or small batches. This flexibility helps businesses test and refine devices before scaling to larger volumes.

Depending on the requirements, features like viewing windows, modular racks, cable entry points, and advanced thermal management can be included. These features ensure the enclosure is purpose-built for its application.

Copyright © 2024 by Xiamen Tongchengjianhui Industry & Trade Co., Ltd. - Privacy policy